Steel structure surface treatment: the dual pursuit of durability and beauty.

Table of Contents

Benefits of Powder Coating for Steel Structures

Steel structures are a common sight in modern construction, providing strength and stability to buildings, bridges, and other infrastructure projects. However, in order to ensure the longevity and aesthetic appeal of these structures, it is essential to apply a surface treatment that can protect against corrosion and enhance their appearance. One popular method of surface treatment for steel structures is powder coating, which offers a range of benefits that make it an attractive option for architects, engineers, and builders alike.

Powder coating is a dry finishing process that involves applying a fine powder of pigment and resin to a surface, which is then heated to form a durable and protective layer. This method of coating offers several advantages over traditional liquid coatings, including increased durability, improved corrosion resistance, and a more environmentally friendly application process.

One of the key benefits of powder coating for steel structures is its exceptional durability. The powder coating forms a tough, protective layer that is resistant to chipping, scratching, and fading, ensuring that the steel structure maintains its appearance and performance over time. This durability is particularly important for outdoor structures that are exposed to harsh weather conditions, as it helps to prevent corrosion and extend the lifespan of the steel.

In addition to its durability, powder coating also offers superior corrosion resistance compared to other types of coatings. The powder coating forms a seamless barrier that protects the steel from moisture, chemicals, and other corrosive elements, reducing the risk of rust and deterioration. This corrosion resistance is essential for steel structures that are located in coastal areas or other environments with high levels of humidity and salt exposure.

Another benefit of powder coating for steel structures is its versatility in terms of color and finish options. Powder coatings are available in a wide range of colors, textures, and gloss levels, allowing architects and designers to achieve the desired aesthetic for their projects. Whether a project calls for a sleek, modern look or a more traditional finish, powder coating can be customized to meet the specific design requirements.

Furthermore, powder coating is an environmentally friendly option for surface treatment, as it does not contain volatile organic compounds (VOCs) or hazardous air pollutants. The powder coating process produces minimal waste, as any overspray can be collected and reused, reducing the overall environmental impact of the coating application. This makes powder coating a sustainable choice for steel structures that are being constructed with an emphasis on green building practices.

In conclusion, powder coating offers a range of benefits for steel structures, including exceptional durability, superior corrosion resistance, versatility in color and finish options, and environmental sustainability. By choosing powder coating as a surface treatment for steel structures, architects, engineers, and builders can achieve the dual pursuit of durability and beauty, ensuring that their projects stand the test of time while maintaining a visually appealing appearance.

Achieving Corrosion Resistance and Aesthetic Appeal with Galvanization

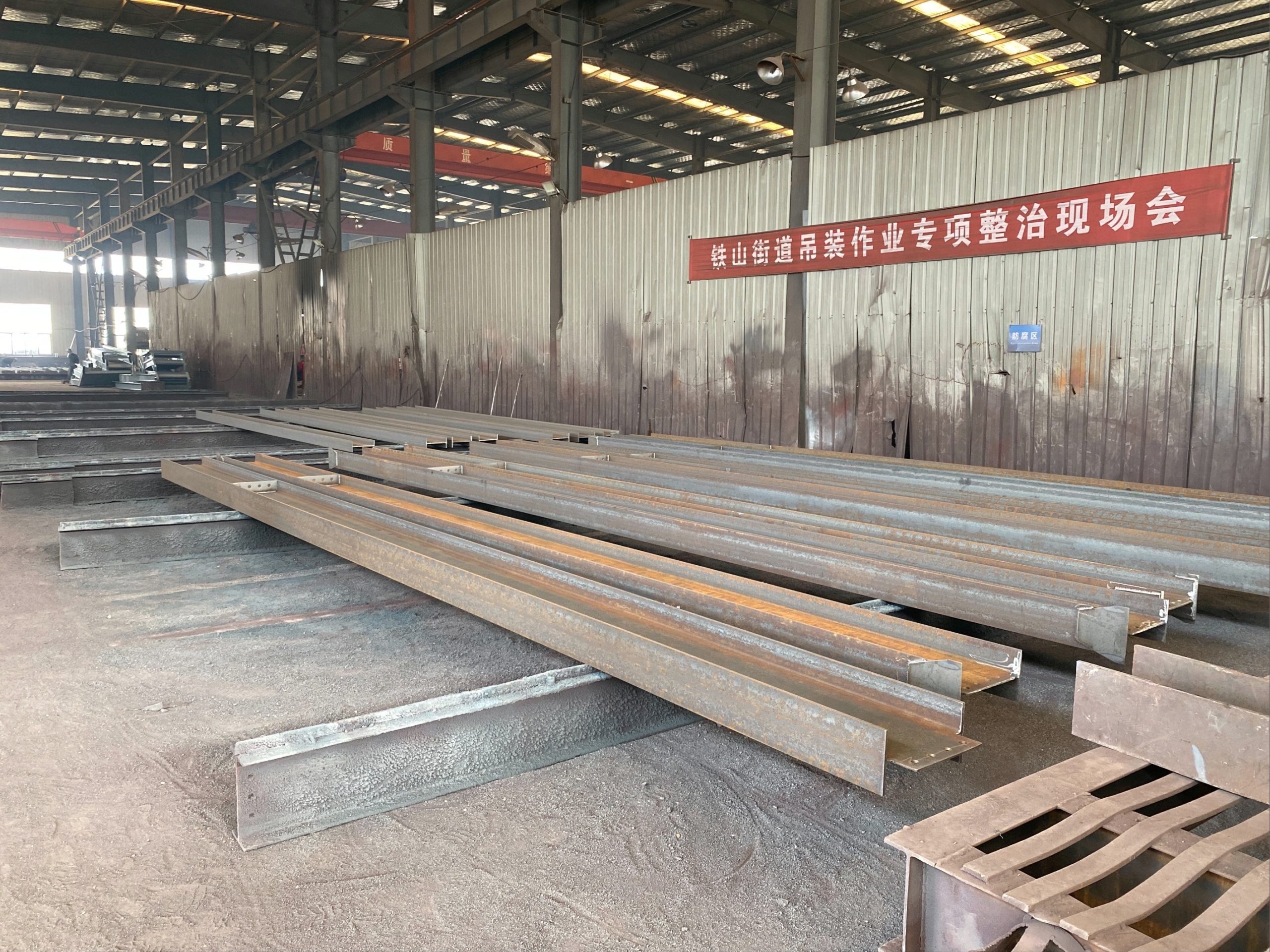

Steel structures are a common sight in modern construction, known for their strength and durability. However, steel is susceptible to corrosion, which can compromise its structural integrity over time. To combat this issue, steel structure surface treatment is essential to ensure both durability and aesthetic appeal. One popular method of achieving this dual pursuit is through galvanization.

Galvanization is a process that involves coating steel with a layer of zinc to protect it from corrosion. This can be done through either hot-dip galvanization or electro-galvanization. Hot-dip galvanization involves immersing the steel in a bath of molten zinc, while electro-galvanization uses an electric current to deposit zinc onto the steel surface. Both methods provide a protective barrier that prevents moisture and other corrosive elements from reaching the steel underneath.

One of the key benefits of galvanization is its superior corrosion resistance. The zinc coating acts as a sacrificial anode, meaning that it will corrode before the steel does. This sacrificial protection extends the lifespan of the steel structure, reducing the need for frequent maintenance and repairs. In addition, galvanized steel is highly resistant to rust, making it ideal for outdoor applications where exposure to the elements is inevitable.

In addition to its practical benefits, galvanized steel also offers aesthetic appeal. The shiny, metallic finish of galvanized steel can enhance the visual appeal of a structure, giving it a modern and sleek appearance. This makes galvanized steel a popular choice for architectural applications where both durability and aesthetics are important.

Furthermore, galvanized steel is versatile and can be easily painted or powder coated to achieve a desired color or finish. This allows for customization and creativity in design, while still maintaining the protective benefits of the zinc coating. Whether used in industrial buildings, bridges, or decorative elements, galvanized steel offers a combination of strength, durability, and beauty.

When considering steel structure surface treatment, it is important to weigh the benefits of galvanization against other options. While there are alternative methods of corrosion protection, such as painting or coating with epoxy, galvanization is often preferred for its long-lasting durability and low maintenance requirements. Additionally, the initial cost of galvanization may be higher than other treatments, but the long-term savings in maintenance and replacement costs make it a cost-effective choice in the long run.

In conclusion, galvanization is a highly effective method of achieving both corrosion resistance and aesthetic appeal in steel structures. By providing a protective barrier against rust and corrosion, galvanized steel ensures the longevity and structural integrity of a building. Its shiny finish and customizable options make it a popular choice for architects and builders looking to combine durability with beauty. When it comes to steel structure surface treatment, galvanization offers a dual pursuit of functionality and aesthetics that is hard to beat.