Development and application prospect of new steel.

Table of Contents

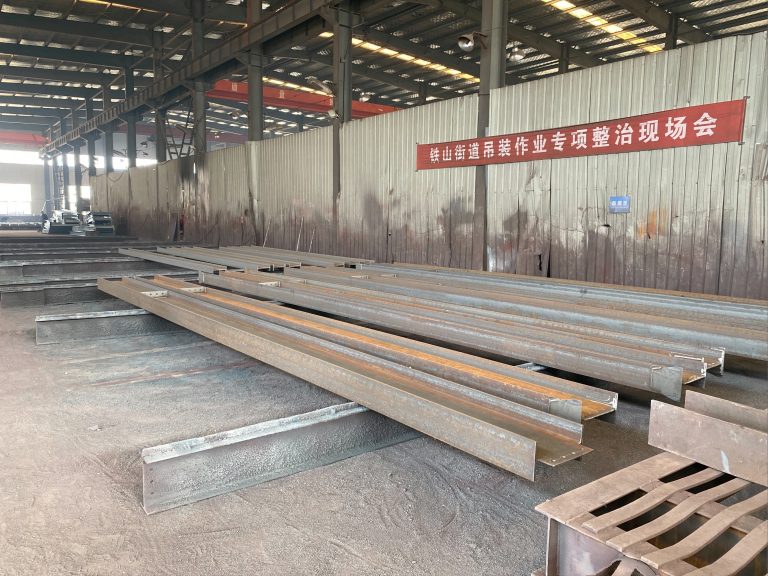

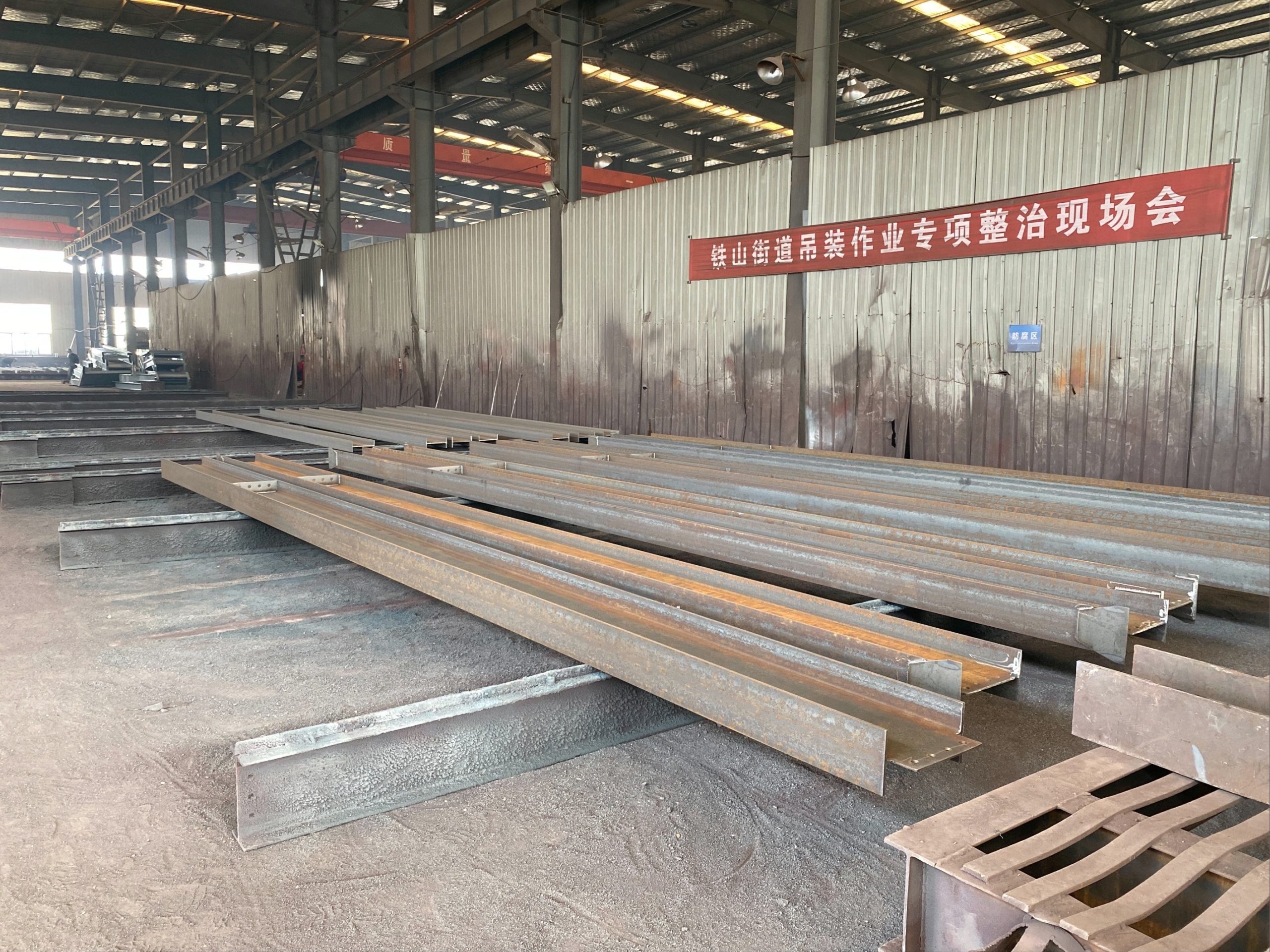

Advantages of Using New Steel in Construction Projects

Steel has long been a staple material in the construction industry due to its strength, durability, and versatility. However, with advancements in technology and materials science, new types of steel have been developed that offer even greater advantages for construction projects. These new steels are engineered to have improved properties, making them ideal for a wide range of applications in the construction industry.

One of the key advantages of using new steel in construction projects is its increased strength. Advanced high-strength steels, such as HSLA (high-strength, low-alloy) steel and AHSS (advanced high-strength steel), have higher yield strengths and tensile strengths than traditional carbon steels. This means that structures built with these new steels can be lighter and more slender while still maintaining the same level of structural integrity. This not only reduces the amount of steel needed for a project but also allows for more innovative and efficient designs.

In addition to increased strength, new steels also offer improved ductility and toughness. This means that they can better withstand extreme loading conditions, such as earthquakes or high winds, without fracturing or failing. This makes them ideal for use in buildings and structures that need to meet stringent safety and performance requirements. Furthermore, the improved ductility of these steels allows for easier fabrication and welding, making them more cost-effective and efficient to work with.

Another advantage of using new steel in construction projects is its enhanced corrosion resistance. Traditional carbon steels are prone to rust and corrosion when exposed to moisture and other environmental factors, which can compromise the structural integrity of a building over time. However, new steels, such as weathering steel and stainless steel, have been specifically designed to resist corrosion and maintain their appearance and performance over the long term. This makes them ideal for use in outdoor structures, bridges, and coastal buildings where exposure to the elements is a concern.

Furthermore, new steels are also more sustainable and environmentally friendly than traditional carbon steels. Many of these steels are made from recycled materials and are fully recyclable at the end of their service life. This helps to reduce the carbon footprint of a construction project and minimize waste generation. Additionally, the increased durability and longevity of these steels mean that structures built with them will require less maintenance and repair over time, further reducing their environmental impact.

Overall, the development and application of new steel in construction projects offer numerous advantages that make them an attractive choice for engineers, architects, and builders. From increased strength and durability to improved corrosion resistance and sustainability, these steels provide a wide range of benefits that can help to enhance the performance, efficiency, and longevity of a construction project. As technology continues to advance and new materials are developed, the future looks bright for the use of new steel in the construction industry.

Future Innovations in Steel Manufacturing and Applications

Development and Application Prospect of New Steel

Steel has been a vital material in various industries for centuries, and its importance continues to grow as new advancements are made in its development and application. In recent years, there has been a significant focus on the development of new types of steel that offer enhanced properties and improved performance. These innovations have the potential to revolutionize industries such as automotive, construction, and aerospace, among others.

One of the key areas of development in new steel is the improvement of its strength and durability. Traditional steel has long been known for its strength, but new alloys and manufacturing techniques are pushing the boundaries even further. High-strength steel, for example, offers a tensile strength that is several times higher than that of conventional steel. This makes it an ideal material for applications where strength is crucial, such as in the construction of bridges and high-rise buildings.

Another area of focus in the development of new steel is its resistance to corrosion. Traditional steel is susceptible to rust and corrosion, which can significantly reduce its lifespan and structural integrity. However, new types of steel, such as stainless steel and weathering steel, have been developed to combat this issue. Stainless steel, for instance, contains a high percentage of chromium, which forms a protective layer on the surface of the steel, preventing corrosion. Weathering steel, on the other hand, forms a stable rust-like appearance when exposed to the elements, providing a natural protective barrier against further corrosion.

In addition to strength and corrosion resistance, new steel is also being developed to offer improved formability and weldability. Formability refers to the ability of the steel to be shaped and molded without cracking or breaking. This is particularly important in industries such as automotive, where complex shapes and designs are required. Weldability, on the other hand, refers to the ease with which the steel can be welded together. New steel alloys are being developed to offer better formability and weldability, making them more versatile and easier to work with.

The application prospects for new steel are vast and varied. In the automotive industry, for example, the use of high-strength steel can lead to lighter and more fuel-efficient vehicles without compromising safety. In the construction industry, the use of corrosion-resistant steel can extend the lifespan of buildings and infrastructure, reducing maintenance costs in the long run. In the aerospace industry, the development of lightweight and high-strength steel alloys can lead to more efficient aircraft designs, resulting in reduced fuel consumption and emissions.

Furthermore, new steel has the potential to revolutionize the renewable energy sector. The development of steel alloys with improved magnetic properties can enhance the efficiency of generators and turbines, leading to increased energy production from renewable sources such as wind and hydroelectric power. Additionally, the use of high-strength steel in the construction of wind turbine towers can enable the installation of larger and more powerful turbines, further boosting energy output.

In conclusion, the development and application prospect of new steel hold great promise for various industries. The continuous advancements in strength, corrosion resistance, formability, and weldability are revolutionizing the way steel is used in automotive, construction, aerospace, and renewable energy sectors. These innovations not only improve the performance and durability of steel but also contribute to the overall efficiency and sustainability of various industries. As research and development in this field continue to progress, we can expect to see even more exciting advancements in the future.