The key role of intelligent manufacturing in the transformation and upgrading of the steel structure industry

Table of Contents

Benefits of Implementing Intelligent Manufacturing in Steel Structure Industry

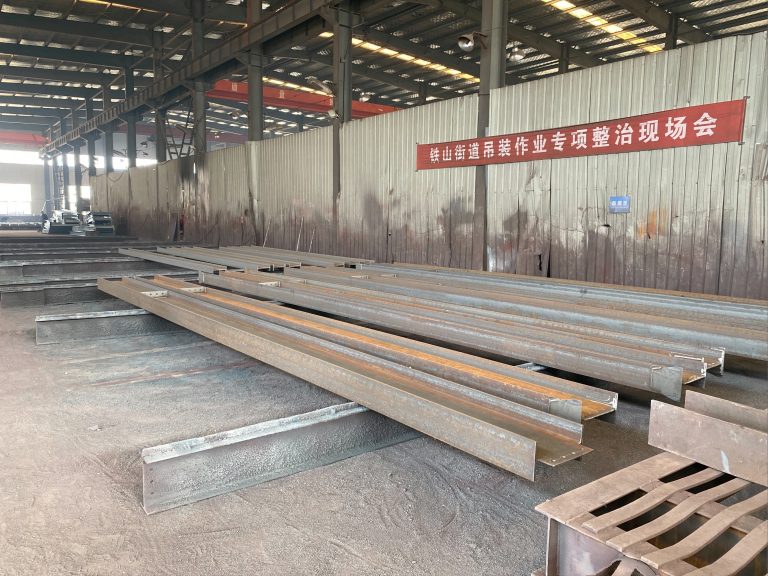

The steel structure industry plays a crucial role in various sectors such as construction, infrastructure, and manufacturing. With the rapid advancement of technology, intelligent manufacturing has become a key factor in the transformation and upgrading of this industry. Intelligent manufacturing refers to the use of advanced technologies such as artificial intelligence, robotics, and data analytics to optimize production processes and improve efficiency. By implementing intelligent manufacturing practices, steel structure companies can enhance their competitiveness, reduce costs, and meet the increasing demands of customers.

One of the key benefits of implementing intelligent manufacturing in the steel structure industry is increased productivity. Intelligent manufacturing technologies enable companies to automate repetitive tasks, streamline production processes, and reduce human error. This results in higher production output and faster turnaround times, allowing companies to meet tight deadlines and deliver products to customers more efficiently. By improving productivity, companies can also reduce lead times and increase their overall competitiveness in the market.

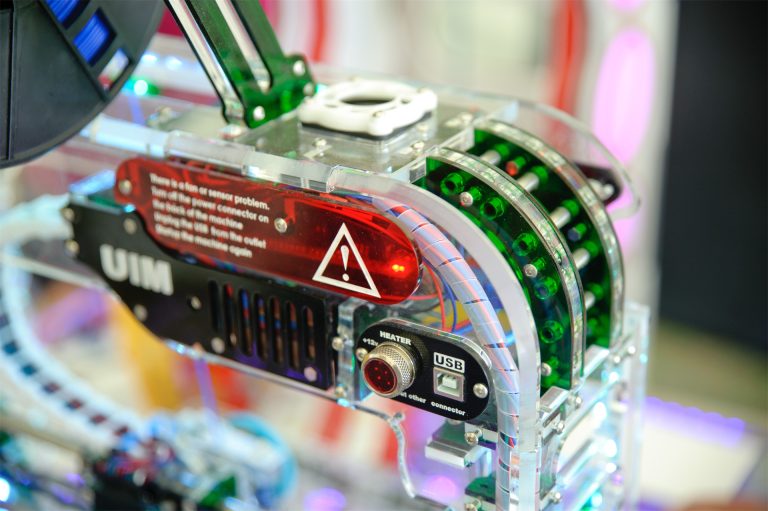

Another benefit of intelligent manufacturing is improved quality control. By using advanced technologies such as sensors and data analytics, companies can monitor production processes in real-time and identify any defects or issues before they escalate. This allows companies to make quick adjustments and ensure that products meet the highest quality standards. Improved quality control not only enhances customer satisfaction but also reduces the risk of costly rework or recalls, saving companies time and money in the long run.

In addition to productivity and quality control, intelligent manufacturing also helps companies reduce costs. By automating production processes and optimizing resource allocation, companies can minimize waste, lower energy consumption, and improve overall efficiency. This results in significant cost savings for companies, allowing them to invest in research and development, expand their operations, and stay ahead of the competition. By reducing costs, companies can also offer competitive pricing to customers, attracting more business and increasing their market share.

Furthermore, intelligent manufacturing enables companies to adapt to changing market demands and trends. By using data analytics and predictive modeling, companies can analyze market trends, forecast demand, and adjust production schedules accordingly. This flexibility allows companies to respond quickly to market changes, launch new products, and capitalize on emerging opportunities. By staying agile and responsive, companies can maintain a competitive edge in the industry and drive growth and innovation.

Overall, intelligent manufacturing plays a key role in the transformation and upgrading of the steel structure industry. By improving productivity, quality control, reducing costs, and adapting to market changes, companies can enhance their competitiveness, meet customer demands, and drive growth and innovation. As technology continues to advance, intelligent manufacturing will become increasingly important for companies in the steel structure industry to stay ahead of the competition and thrive in the global market.

Future Trends and Innovations in Intelligent Manufacturing for Steel Structures

The steel structure industry has long been a cornerstone of modern construction, providing the framework for buildings, bridges, and other infrastructure projects around the world. As technology continues to advance, the industry is undergoing a transformation and upgrading process to meet the demands of the future. Intelligent manufacturing is playing a key role in this evolution, revolutionizing the way steel structures are designed, fabricated, and assembled.

One of the primary benefits of intelligent manufacturing in the steel structure industry is increased efficiency. By utilizing advanced technologies such as artificial intelligence, robotics, and automation, manufacturers are able to streamline production processes and reduce waste. This not only leads to cost savings but also allows for faster project completion times, enabling companies to meet tight deadlines and deliver high-quality products to their customers.

In addition to efficiency gains, intelligent manufacturing also enhances the quality and precision of steel structures. Advanced software programs and modeling techniques enable engineers to design complex structures with greater accuracy, ensuring that each component fits together seamlessly. This level of precision not only improves the overall aesthetic of the finished product but also enhances its structural integrity, making it more durable and resistant to wear and tear.

Furthermore, intelligent manufacturing is driving innovation in the steel structure industry by enabling the development of new materials and construction techniques. For example, 3D printing technology is being used to create intricate steel components that would be impossible to produce using traditional methods. This opens up new possibilities for architects and designers, allowing them to push the boundaries of what is possible in terms of form and function.

Another key advantage of intelligent manufacturing in the steel structure industry is its ability to improve safety standards. By automating dangerous or repetitive tasks, manufacturers are able to reduce the risk of workplace accidents and injuries. Additionally, advanced monitoring systems can detect potential issues before they escalate, allowing for timely intervention and preventative maintenance.

As the demand for sustainable and environmentally friendly construction practices continues to grow, intelligent manufacturing is also playing a crucial role in helping the steel structure industry reduce its carbon footprint. By optimizing production processes and minimizing waste, manufacturers are able to lower their energy consumption and emissions, making their operations more eco-friendly.

Looking ahead, the future of intelligent manufacturing in the steel structure industry is bright. As technology continues to evolve, we can expect to see even greater advancements in automation, robotics, and artificial intelligence. These innovations will not only further improve efficiency, quality, and safety but also open up new opportunities for customization and personalization in steel structure design.

In conclusion, intelligent manufacturing is revolutionizing the steel structure industry, driving transformation and upgrading processes that are shaping the future of construction. By embracing advanced technologies and innovative practices, manufacturers are able to meet the demands of a rapidly changing market and deliver high-quality, sustainable products to their customers. As we look to the future, it is clear that intelligent manufacturing will continue to play a key role in driving innovation and growth in the steel structure industry.